Our history

Since 2014, BEST Systemy Grzewcze has been operating in Wałbrzych Special Economic Zone. 2 years later, we moved to our new, modern headquarters, situated at Towarowa 15, Świdnica.

HISTORY OF OUR COMPANY

21.12.1990

A start-up!![]() BEST Instalatorstwo Sanitarne, c. o i gazowe - Świdnica, ul. Kołłątaja 21

BEST Instalatorstwo Sanitarne, c. o i gazowe - Świdnica, ul. Kołłątaja 21

21.12.1990

1990-1992

Heating systems

Installation of heating and plumbing systems in private buildings

1993

Central heating and plumbing systems Installation of central heating and plumbing systems, using PVC technology

Installation of central heating and plumbing systems, using PVC technology

1993

1994

Collaboration Setting up a business collaboration with TTI HAGEN, Germany

Setting up a business collaboration with TTI HAGEN, Germany

1994

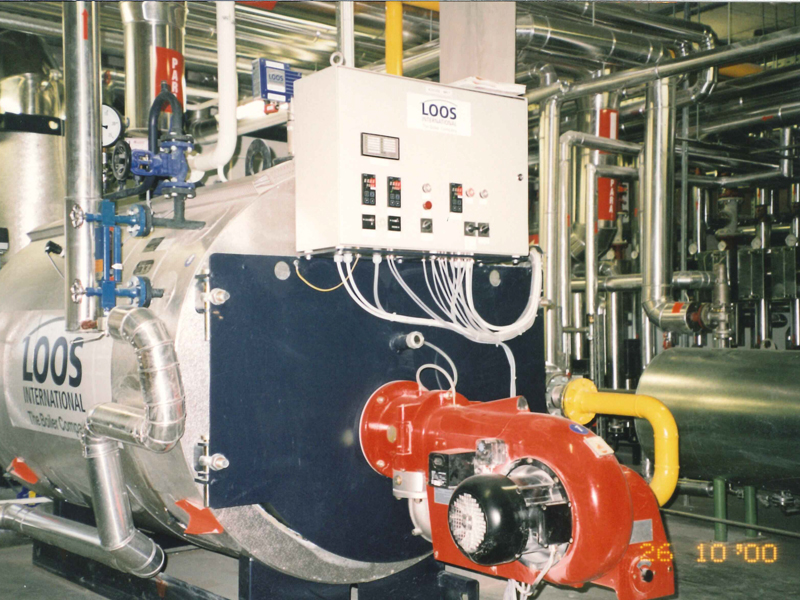

Collaboration![]() Establishing a business cooperation with LOOS Centrum from Warsaw

Establishing a business cooperation with LOOS Centrum from Warsaw

1994

1994

1994

1994

1995

1995

Design of the logo of BEST

Design of the logo of BEST1995

1995

1996-1997

1996-1997

1998

1999

1999

1999

1999

1999

Sience 2000...

2000

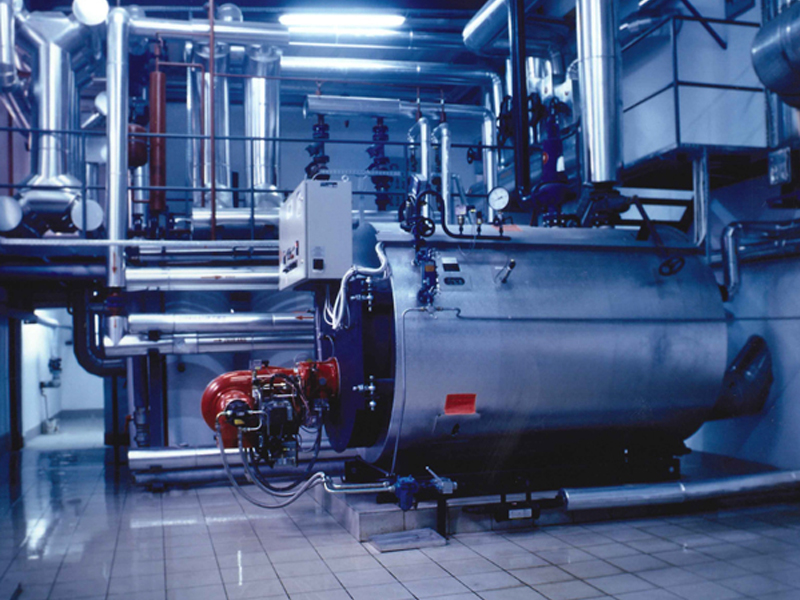

Installation of the steam boiler plan, with a capacity of 8t/h, for YTONG, Sieradz

Installation of the steam boiler plan, with a capacity of 8t/h, for YTONG, Sieradz2000

2000

2000

2000

2001 - 2002

2002

2002

2002

2003

2003

2003

2003

2003

2003

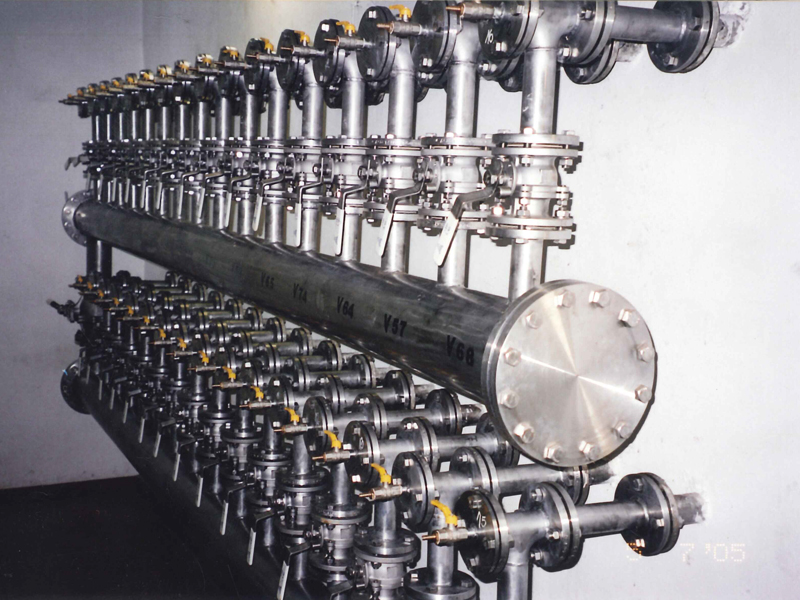

2005

2005

2004 - 2007

2008

2008

2008

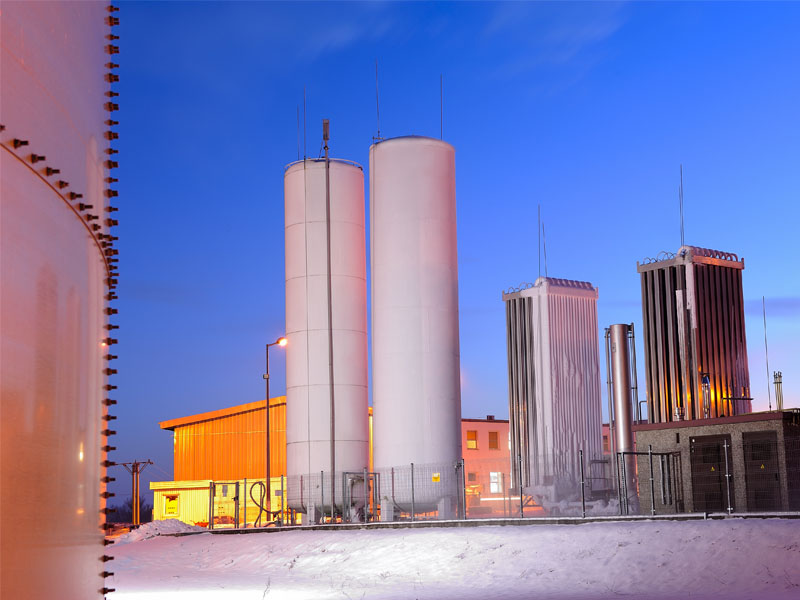

Entering into cooperation in terms of LNG distribution

Entering into cooperation in terms of LNG distribution2009

2009

2009

2010

2010

2010

Design documentation of exhaust gas heat recovery system in glass melting furnaces of glass factory in Jarosław

2011

2011

2011

2012

2012

2012

2013

BEST PHU Mariusz Koba forms the new economic entity: BEST sp. z o.o

BEST PHU Mariusz Koba forms the new economic entity: BEST sp. z o.o2013

2014

2014

Implementation, for the first time, of the Quality Requirements for Welding PN-EN ISO 3834-2:2007 Standard

Implementation, for the first time, of the Quality Requirements for Welding PN-EN ISO 3834-2:2007 Standard2014

2014

2014 - 2015

2014 - 2015

2016

2016

2016

2018

2018

2018

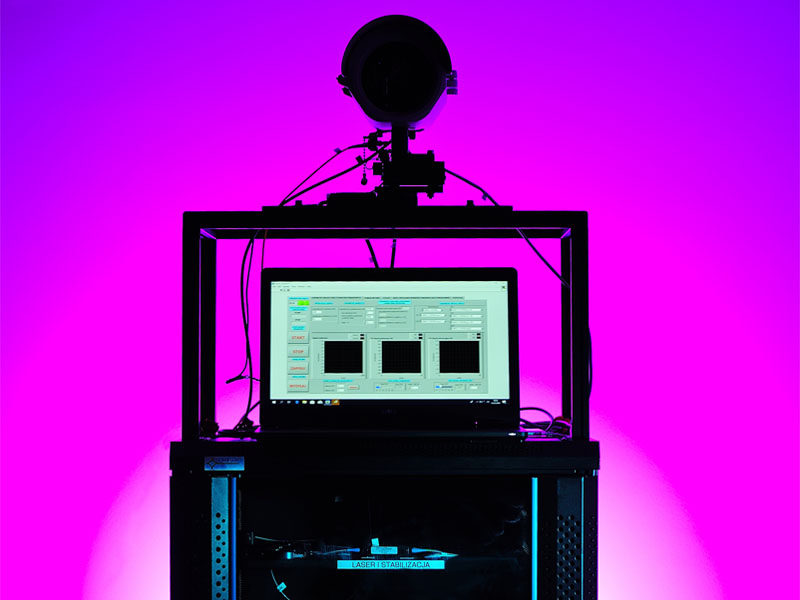

2019

2019

2019

2020

2020